3D Printing: Revolutionizing Road Sweeping Companies

The road sweeping industry plays a crucial role in maintaining clean and safe streets and highways. Over the years, advancements in technology have continuously improved the efficiency and effectiveness of road sweeping companies worldwide. One such technological innovation making waves in the industry is 3D printing.

The Power of 3D Printing

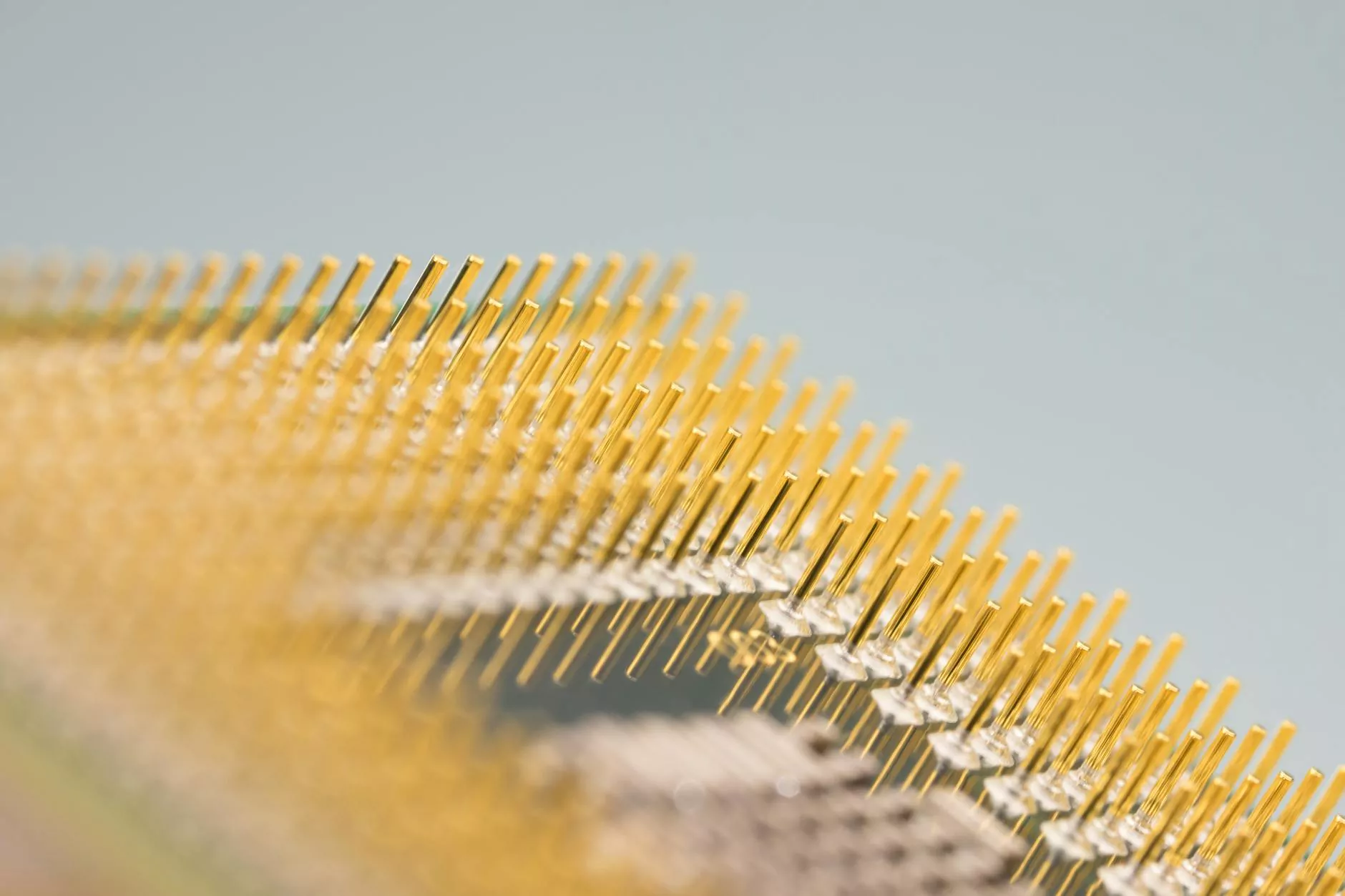

3D printing, also known as additive manufacturing, is a revolutionary process that allows objects to be created by layering materials based on a digital design. This technology has found its way into various industries, and road sweeping companies are no exception.

Traditionally, road sweeping equipment and components required extensive manufacturing processes, involving multiple stages and various suppliers. This often led to longer lead times, higher costs, and limited customization options for road sweeping companies. However, with the integration of 3D printing, these limitations are becoming a thing of the past.

Enhanced Efficiency and Customization

With 3D printing, road sweeping companies can now benefit from enhanced efficiency and customization in their equipment. The ability to obtain parts on-demand significantly reduces lead times, ensuring that the sweeping machines are in top-notch condition at all times. It also allows for rapid prototyping and testing of new designs, accelerating innovation in the industry.

Furthermore, road sweeping companies can now customize various components to meet specific operational needs. This level of customization ensures that the equipment performs optimally under different sweeping conditions. Whether it's modifying brush heads, adjusting suction power, or incorporating specialized sensors, 3D printing offers unprecedented flexibility for road sweeping companies.

Economical and Sustainable Solutions

Another advantage of 3D printing for road sweeping companies is the potential for cost savings and sustainability. By locally producing parts and components, companies can reduce transportation costs and dependency on external suppliers. This not only speeds up the manufacturing process but also minimizes the environmental impact associated with long-distance shipping.

Additionally, the use of 3D printing enables road sweeping companies to optimize material usage, reducing waste and promoting sustainability. With traditional manufacturing methods, excess materials often end up in landfills. However, 3D printing allows for precise and efficient use of materials, minimizing waste and conserving resources.

Future Possibilities

The advancements in 3D printing technology continue to push the boundaries of what is possible in the road sweeping industry. As the technology becomes more sophisticated and accessible, road sweeping companies can look forward to even more exciting developments in the future.

One such possibility is the creation of entirely new designs that enhance sweeping efficiency and reduce energy consumption. With the ability to print intricate shapes and structures, 3D printing opens doors for innovation that may result in more sustainable road sweeping practices.

Moreover, the adoption of 3D printing allows road sweeping companies to embrace a more proactive approach to maintenance. By being able to quickly replace worn-out parts and components, companies can significantly reduce machine downtime, ensuring that the streets are always clean and tidy.

Conclusion

3D printing is undoubtedly revolutionizing the road sweeping industry, providing road sweeping companies with a competitive edge in terms of efficiency, customization, economics, and sustainability. The ability to produce parts on-demand, customize designs, and reduce waste are just some of the benefits that this technology brings to the table.

As road sweeping companies continue to embrace 3D printing, we can expect to see a cleaner, more efficient, and environmentally friendly industry. With ongoing technological advancements, the future holds tremendous potential for further innovation and optimization in road sweeping practices.